Welding Health and Safety Update | Mild Steel Welding Fumes Reclassified

From February 2019, anyone who undertakes welding activities, regardless of industry must be protected against welding fumes. This comes as a result of new scientific evidence from the International Agency for Research on Cancer. The new findings reveal exposure to welding fumes can cause lung cancer. There’s also a suggestion that it might even lead to kidney cancer as well.

The Workplace Health Expert Committee has endorsed the reclassification of mild steel welding fume as a human carcinogen.

The Workplace Health Expert Committee has endorsed the reclassification of mild steel welding fume as a human carcinogen.

Following on from this, there is a strengthening of the Health and Safety Executive's (HSE) enforcement expectation for all welding fumes. This is because general ventilation does not achieve the necessary control.

Exposure to some welding fumes can cause metal fume fever, most commonly caused from welding galvanised steels.

Health & Safety Welding Update

If you'd like to see the official safety alert on Health and Safety Executive website, please see here. The HSE have specific guidance which outlines control measures to consider when welding in a variety of environments. In all cases where RPE is required, a minimum Assigned Protection Factor (APF) of 20 is outlined.

*Disclaimer* This article is our interpretation of the new safety guidance. Axminster Tools & Machinery do not necessarily endorse any suggestions, solutions, or third party products that may be mentioned. Please use the information at your own discretion. Axminster Tools & Machinery does not guarantee that these links will be maintained or functional at any given time. For more information, we encourage you to read the official HSE Safety Bulletin: STSU1- 2019.

What it means for businesses

Anyone who welds indoors, be it workers, employers, self-employed tradespeople or contractors, should ensure effective engineering controls are provided, for example, Local Exhaust Ventilation (LEV).

In instances where LEV alone does not adequately control exposure then adequate and suitable Respiratory Protective Equipment (RPE) should be added. This type of equipment will help to protect against the residual fume. Extraction will also control exposure to manganese, which is present in mild steel welding fume and can cause neurological effects similar to Parkinson’s disease.

In instances where LEV alone does not adequately control exposure then adequate and suitable Respiratory Protective Equipment (RPE) should be added. This type of equipment will help to protect against the residual fume. Extraction will also control exposure to manganese, which is present in mild steel welding fume and can cause neurological effects similar to Parkinson’s disease.

Likewise, appropriate RPE should also be provided for welding outdoors. To adequately safeguard health, welders should be suitably trained and instructed in the use of these controls.

Remain compliant

Remain compliant

HSE will cease to accept any welding undertaken without any suitable exposure control measures in place. This is because there is no known level of safe exposure. With this in mind, two steps need to be addressed.

Firstly, a proper RPE programme should be put in place to ensure suitable product selection including face fit testing, inspection, maintenance, cleaning and storage. Secondly, risk assessments should reflect the change in the expected control measures.

Respiratory protection for welding tasks

JSP SpringFit Valved Respirator FFP3 Carbon Layer

Offering a high protection FFP3 level, these SpringFit fold flat disposable masks incorporate an activated carbon layer to remove nuisance odours. Supplied in packs of 10, each individually wrapped.

-

JSP SpringFit™ Fold Flat Valved Respirator FFP3 Carbon Layer (Pkt 10)From £28.98 £24.15 From £26.09

JSP SpringFit Fold Flat Valved Respirator FFP3

These disposable masks feature the Typhoon™ valve, which reduces breathing resistance, heat and moisture build-up. Supplied in packs of 10, each individually wrapped.

-

JSP SpringFit™ Fold Flat Valved Respirator FFP3 (Pkt 10)From £24.98 £20.82 From £22.49

JSP Force 8 Reusable Half Mask Complete Medium P3

The Force™ 8 features the Typhoon™ valve, which has very low breathing resistance, allowing you to breathe comfortably without fatigue. Furthermore, the Force™ 8 Press To Check™ filters allow you to instantly check that you have the correct seal every time.

-

JSP Force™ 8 Reusable Half Mask Complete Medium P3From £26.58 £22.15 From £23.93

-

JSP Force™8 and Force™ 10 - PressToCheck™ P3 Filters - (Pkt 2)From £12.18 £10.15

-

JSP Force™ 8 and Force™ 10 - PressToCheck™ A2 P3 Filters - (Pkt 2)From £25.48 £21.23

Important factors to consider

- Always read and follow the manufacturer's instructions, fitting, maintenance and storage requirements.

- Ensure you've been trained and face fit tested before wearing the RPE for the first time.

- Make sure any RPE is subject to an RPE programme. An RPE programme encapsulates all the elements of RPE use you need to ensure that your RPE is effective in protecting you.

- Check the compatibility of your RPE with other Personal Protective Equipment (PPE).

- Inspect your RPE for dirt and damage, both before and after fitting.

- To provide a tight fit when the mask is worn, make sure you are clean shaven especially around the seal area.

Need help?

With an ever-expanding range on our website and stores across the country, Axminster offer a great selection of health and safety products. If you'd like to know more about what the new health and safety update means for you, get in touch with our Axminster experts today.

Get in touch

To arrange a visit with your regional Technical Consultant phone 0800 371822, email abst@axminster.co.uk or complete this form. Find out more about our Business Services team at axminster.co.uk/business.

Discover more...

Discover more...

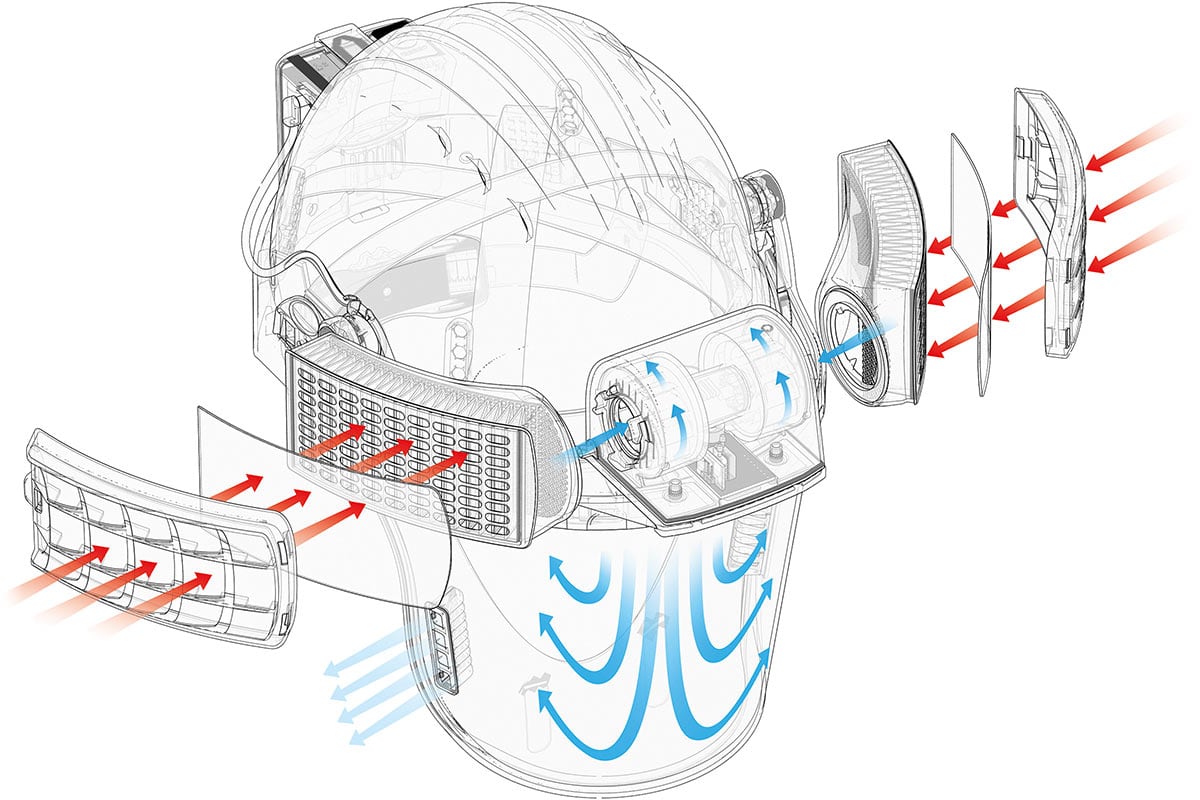

If you’ve enjoyed reading this helpful guide, why not take a look at other related articles? Firstly, our informative First Look guide to the PowerCap® Infinity® Respirator is worth a read. It is JSP’s first four-in-one head unit and offers users complete above the head protection. Inspired by feedback received from users who frequently wear Powered Air Purifying Respirators (PAPR), the respirator is designed for industrial environments.

Next, Festool's CTM MIDI CLEANTEC dust extractor is perfect for when you’re on the go. This dust extractor extracts class M dusts on the construction site with minimal impact on health. Read our informative Insights guide to find out more. Lastly, anyone can suffer financial loss as a result of long term sick leave due to injury at work. Not only is it the law, there are measures you can take to reduce risk by using the correct Personal Protective Equipment (PPE).

Get involved!

Do you carry out welding tasks? If so, we’d love to hear from you. Get in touch and tell us your thoughts about the new health and safety update. Better still, show us your creations! Either comment below, or get in touch via one of our social media platforms. Find us on Facebook, send us a tweet or connect with us on Instagram using #welding to @AxminsterTools.