Get the Right Table Saw for You

Why would you buy one?

For many woodworkers; amateur, trade or professional, the table saw is often a key item in the workshop and the starting point for many projects. Having the ability to perform a multitude of different tasks such as ripping, cross cutting and sheet material preparation, the correct table saw becomes an indispensable part of the workshop. It is probably the first machine that many would contemplate purchasing. However, the most important consideration is to understand exactly what the ‘correct’ table saw should be for any given application.

Moreover, it’s essential that it has the appropriate strength, longevity and capacity but above all, it has to be accurate.

Applications

Table saws vary in size, function and price. Therefore it’s of great benefit to consider the probable applications when drawing up a shortlist.

In a hobbyist or amateur workshop, and in some trade workshops, a table saw might be called upon to perform a whole host of different tasks where a ‘general purpose’ machine is appropriate. Other more specialist establishments may require a large dedicated panel or rip saw.

For example, if fine furniture or restoration work is produced in the workshop, the machine may be called upon to cut solid baulks of heavy timber. In this instance, a good depth of cut, solid fence and powerful motor are important considerations.

Should panel or sheet board be the primary material cut on the saw, the maximum ripping distance from blade to fence and a good quality sliding carriage with support either side will be paramount. When veneered sheets are being cut, a scoring blade to minimise chipping on the underside is highly desirable.

Key Features of a Table Saw

Weight

The weight of a machine is an important consideration. The heavier it is, the more stable the machine becomes in use and vibration will be kept to a minimum. It also provides a good indication of the quality of the internal components used during the manufacture. Unless a portable machine is required for site use, a cast iron table saw is far better for supporting large sheets or heavy, solid timbers.

The Table

Whichever machine is eventually chosen, the table is the main support and datum for the timber being sawn. It should be smooth, flat and strong. With the exception of the very lightest, portable Hobby Series BTS10ST saw with an extruded aluminium table, all the other Axminster saws have finely ground, cast iron tables. These provide an accurate surface for your work, as well as providing additional mass to damp out vibrations.

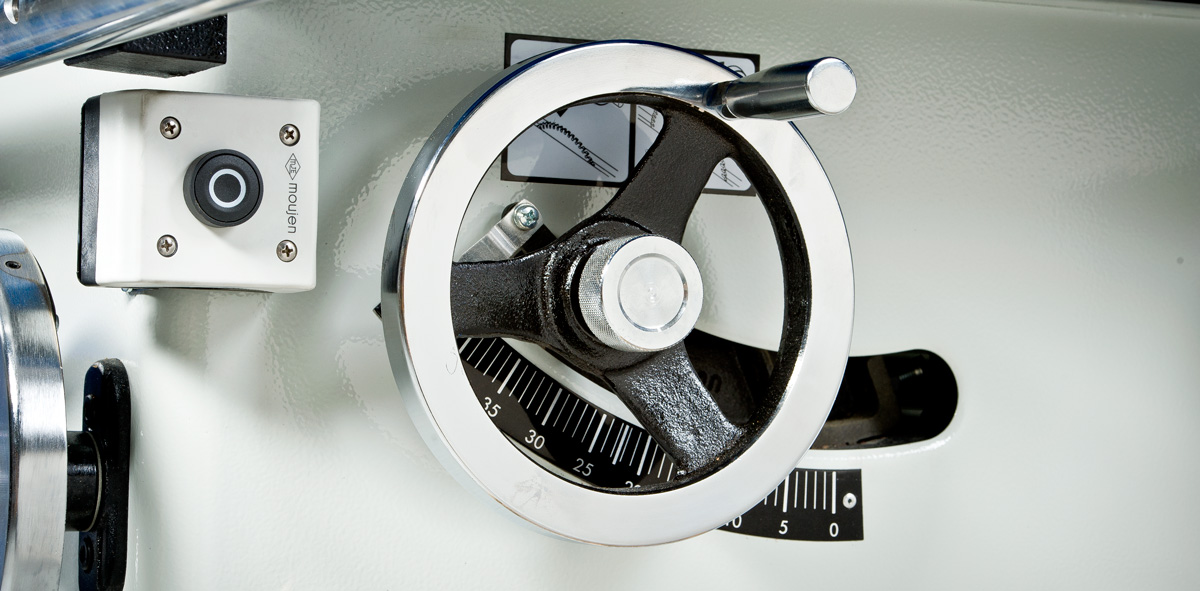

Blade Rise, Fall and Tilt

Using a table saw safely, accurately and to its full capacity means that it is necessary to adjust the height of the blade as well as its angle. The portable Hobby Series BTS10ST table saw is the only machine where the height and tilt controls are grouped together; all the other machines feature separate handles and mechanisms with acme threads for precise, easy height adjustment and accurate tilt of the blade.

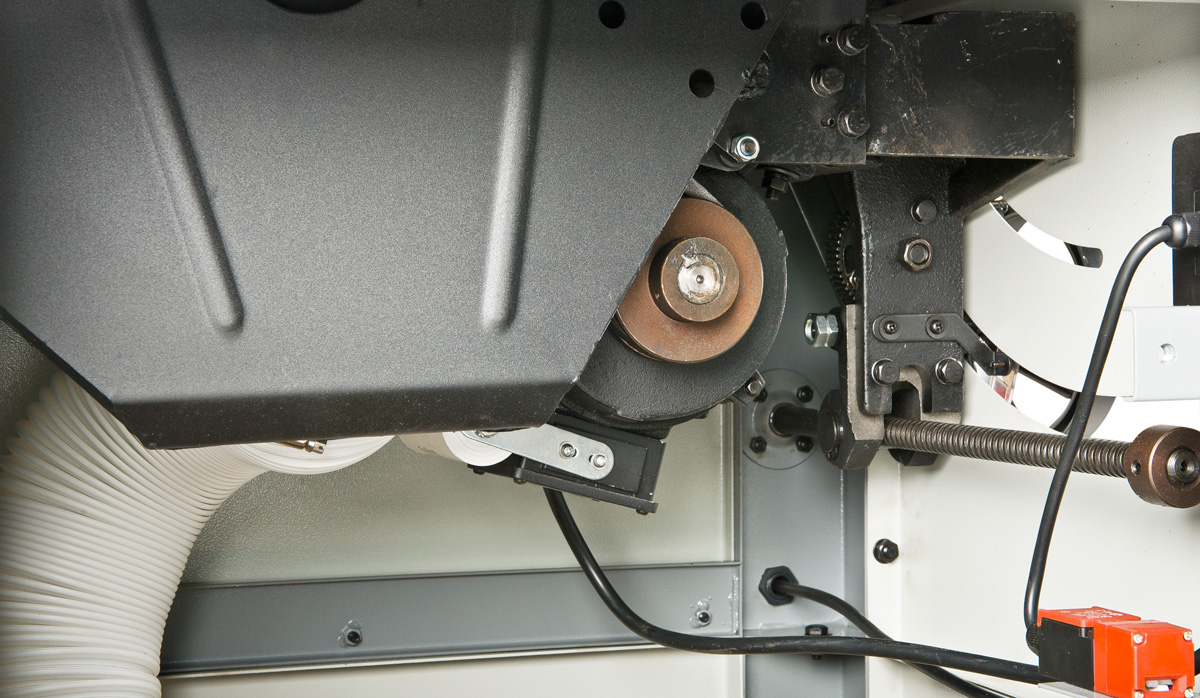

Internal Construction and Trunnions

The trunnions on a table saw are crucial as it is this mechanism that supports the motor and saw unit. It should be robustly constructed in order to provide the strength and rigidity to enable it to carry the considerable weight of the motor as well as both the saw blade adjustment mechanisms. Cast iron is the material of choice as it meets all the requirements, whilst adding extra weight to the saw. The trunnions are machined for accurate and smooth operation when tilting the saw blade. They are bolted to the frame to further isolate the table from any vibration and provide added support.

Rip Fence and Rails

Accurate ripping or straight cutting requires a dependable and precise rip fence. It should be sturdy enough to provide support to the wood as well as providing adjustment to ensure accuracy in relation to the blade and table. You should be able to adjust the fence so that it ends just past the centre position of the blade. This will avoid the timber binding against the fence, the result of which may be ‘kickback’. Axminster Hobby and Trade Series fences and rails are made from extruded aluminium whilst the heavier industrial saws use a solid steel rail and cast iron rail mountings.

Mitre Fence and Slots

Table saws are provided with twin slots; one each side of the blade which means that the mitre fence can be used in either. All table saws are provided with mitre fences and you can upgrade these if you deem it necessary. The accuracy of the cut will be improved if the sliding table accessory is used with the saw. This is due to the movement tolerance of the mitre fence in the slot being removed.

Sliding Tables

All Axminster table saws feature a movable table on the left hand side of the blade. This is either a built-in beam, which is part of the table itself and runs close to the edge of the blade, or an optional sliding table accessory. Both of which will enable more accurate mitre cuts in addition to giving more support when sawing sheet materials.

The sliding tables are easy to fit and adjustable to run parallel to the blade. When not required, they can be easily removed for storage, creating more space in the workshop. The larger sliding tables on dedicated Trade and Industrial Series panel saws are an integral part of the machine and consist of a telescopic support arm with a cross-cut table and movable beam.

Health and Safety

A table saw of any description, used carelessly or incorrectly, is one of the most dangerous machines in the workshop. They can have the potential to cause life-threatening injuries. Basic health and safety precautions should always be observed when using one.

In order to avoid ‘kickback’ i.e. the timber being caught by the blade and thrown back towards the operator, always stand to the left hand side, never in the ‘field of fire’. Whenever performing rip cuts, always use a push stick or guide block so that your hands stay well clear of the blade. In businesses, table saw operators should use a push stick that is no smaller than 450mm (HSE requirement). Using a sliding table or mitre fence running in a slot is much safer as there is much more support. However, a hand span distance away from the blade is still recommended.

All Axminster table saws are fitted with a mandatory crown guard and riving knife that should never be removed when the saw is in use. In a professional workshop in the UK, it's illegal to remove these two items from a table or panel saw.

When cutting, table saws inevitably produce large amounts of dust. This is a health concern and should be removed at source by an efficient, dedicated dust extractor. Alternatively, the table saw should always be plumbed into a piped extraction system. Table saws are generally fitted with 100mm extraction ports as well as a smaller ‘take-off’ port on the crown guard, that aids the removal of saw dust directly over the blade.

Finally...

There are many different factors to consider when buying a table saw. Not only are these the features of the saw and how they will work for you but also your own personal circumstances. How much you will be using the saw. The jobs you need to do. Let's not forget, a key considerations is how much space you have available. The list is endless.

We hope this guide has gone some way to helping you know the key features of a table saw. With the goal of matching these up to your needs. Remember, the saw is only as good as the blade you put in it. If you need some help on finding the blade you need, this guide should help.

Hi,

It is your blog is best for me and i am decided by buy.

Great close up picture of fingers up close to blade immediately adjacent to caption describing current H&S minimum safety distance regs!

Hi Michael. Very good spot here! We can only apologise about this.

After reviewing the HSE guidelines, it's actually the size of the push stick that should be 450mm rather than the distance from the blade that your hands should be. So this will be amended right away.

A push stick is recommended when using a rip fence, but when using a sliding table/mitre fence running in a slot, a hand span distance is appropriate.

Apologies about the confusion, we will update with this information shortly.

Thanks, Mark