My Favourite Router Cutters Plus A Few Do’s and Don’ts

A short while ago I dipped briefly into a couple of issues to do with router tables and, as a consequence, it’s worth looking at some of the cutters that you or I might I use in one. It’s really an open-ended question because so much depends on the type of work that we do and one person’s choice of cutters may be completely different to the next.

Whenever possible, I try and use cutters with a ½” shaft rather than ¼”, as using one with a little more steel in it gives an added feeling of security, especially if I intend to take a reasonably heavy cut. It’s not always possible to get hold of these sorts of cutters, but they’re the ones I always tend to choose.

Cutters also need to be inserted far enough into the collet so that it can be tightened sufficiently to hold them. If they’re not pushed in far enough, there’s the very real probability that something quite nasty is going to happen to a piece of steel spinning at 25,000rpm.

As well as this sort of damage, cutters need to be gripped tightly...really tightly! On more than one occasion, I hadn’t done up the collet quite tight enough and I was moderately surprised to see that my intended groove or rebate, of say 8mm deep, had in fact increased to 10 or 12mm at one end. The very rapid conclusion that I came to was that the cutter was sliding up the collet and would eventually depart company with it, the consequences of which didn’t really bear thinking about.

In the same way as all other tools and equipment, router cutters and collets need to be maintained. In a previous article, I mentioned that I’ve modified the storage racks on my UJK Technology Professional Table but the most common method for keeping cutters is the foam presenter mat which can be cut to any convenient size to fit the bottom of a drawer. Properly arranged, the storage of cutters in one of these mats ought to prevent the very hard and brittle carbide edges from clunking against one another.

Trend do quite a good kit for router and collet maintenance which includes a PTFE lubricant, some anti-corrosion fluid, a DMT stone as well as a selection of brass brushes, which are used to keep the inside of the collets clear of resin and routing debris. Cutters should be kept in good condition which includes cleaning and also sharpening. This should only ever be done on the inside edge of the carbide as sharpening the outside will very quickly reduce the overall profile of the cutter. As it is, sharpening the inside edge will still alter the diameter, but not so much or so rapidly.

To sharpen the cutter, place the stone on the bench so it overhangs slightly, then pass the cutter over it a few times to refresh the edge. It won’t be the same as a brand new cutter, but the life can be extended somewhat so that it’s respectable for a while longer.

Some larger cutters (which are always supplied with a ½” shaft) can have a very large diameter and it’s imperative that the speed is kept to that which is recommended (12000rpm) and they must never, ever be used in a hand-held router...they’re for table use only.

In no particular order of preference, these are the main cutters that I use (some more than others) for most of my activities in the ‘shop:

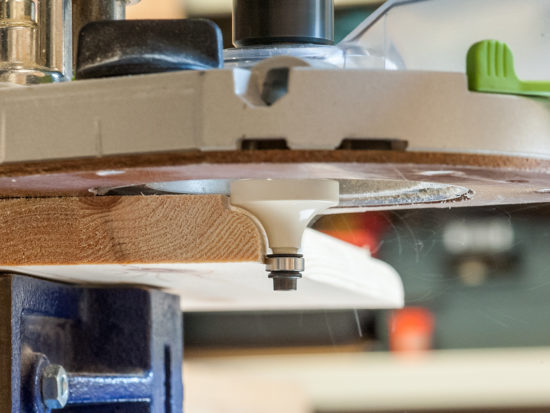

• Rebate Cutters - over the years, I’ve accumulated several of these cutters which see fairly frequent use and changing the bearing allows a different size of rebate to be machined; especially useful for boxes and small cabinet backs.

• Dovetail Cutter - a handy cutter to have in your collection as it enables a dovetailed keyway to be cut along with a corresponding tongue. Always remove the centre section with a parallel cutter, otherwise the depth of cut is liable to be too great for one pass.

• Keyhole Cutter - one of these is useful to keep for making jigs, fixtures and fittings. The recently introduced Tee Slot Cutter for Track Clamps will enable the Axminster Trade Quick Lever Guide Rail Clamps to be used elsewhere on the bench apart from their normal use in plunge saw track.

• Bearing Cutters - these cutters are indispensable for template work in the router table. Although cutters are available as either a ‘top’ or ‘bottom’ variant, it’s the top version which is used in the router table.

• Twin Flute with Bottom Cut Insert - I have a fairly decent set of these cutters in many different sizes and they’re the ones that I use most of the time. If machining a groove, the insert allows it to cut the bottom which also enables it to plunge effectively when used in a hand-held router at the bench.

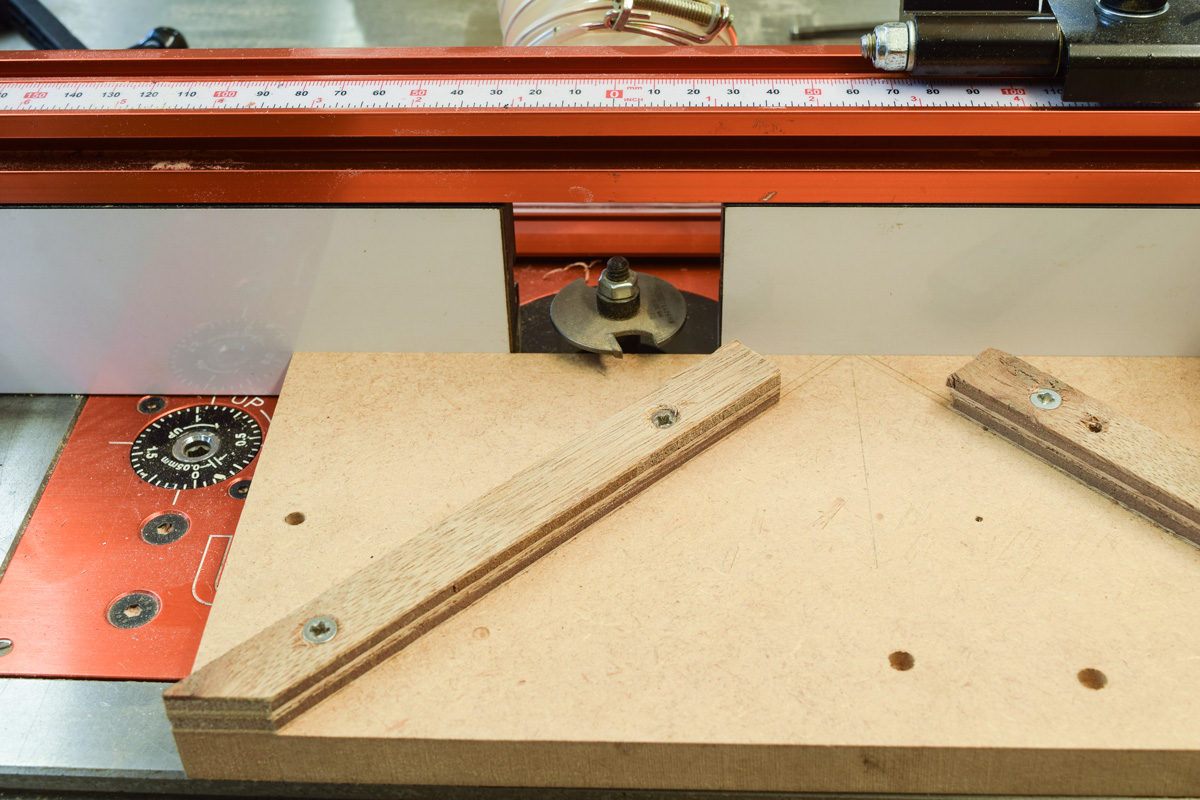

• Slot Wing Cutter - this cutter needs to be used with an arbour and is ideal for cutting the reinforcing slots used on the mitred joints on picture frames and boxes.

Shown in the picture is the jig I now use with a slot wing cutter and it consists of an oddment of mdf with a couple of battens screwed onto it at 45°. When the work is placed inside the 90° angle, the corner to be machined will be level with the edge of the jig. In use, it’s important to pass the work through once; making a second cut is liable to lead to inaccuracies as the cutter may not necessarily follow the same path through the existing slot.

The 4mm slot wing cutter is an alternative method of producing the slots for biscuits, particularly if the work is quite narrow as in lipping, where it may be quite awkward to use a conventional biscuit jointer.

These are the most commonly used cutters in my ‘shop, but there are many others which aren’t used so much and have been purchased for a specific application, or as part of my initial set. Apart from replacing them when they become ‘tired’ I now only buy cutters as and when they’re needed.