EcoPoxy in Education | Andrew's Project

Student, Andrew Mills’ use of EcoPoxy predominantly began as research for his BA Hons degree dissertation at university. Andrew discovered a product named ‘Solidwool’ which he was immediately intrigued by; not only for its aesthetic form but also due to all the potential applications it could be used for. Research led Andrew to experiment in making it himself and, as he wanted to keep it as eco-friendly as possible, EcoPoxy became the ideal choice of partner.

As Andrew's project began to unfold, he decided that he wanted to use EcoPoxy within more of his designs. The initial research from the dissertation is intended to influence the end of the year project but Andrew decided to bring its influence forward.

The experimentation started on a small scale, simply to gauge whether his ideas would work as he had hoped. Andrew built a small former using melamine coated board, calculated the internal area and converted it to millilitre volume. Unfortunately, Andrew hit a snag when he forgot to use any releasing agent, meaning the melamine stuck to one side

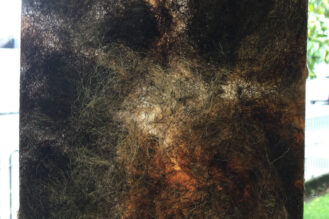

A second attempt was made in a larger former with the hand screw press. Andrew used a wax furniture polish as a release agent. This solved the issue and created a 2mm thick sheet that was partially see-through and resembled alabaster.

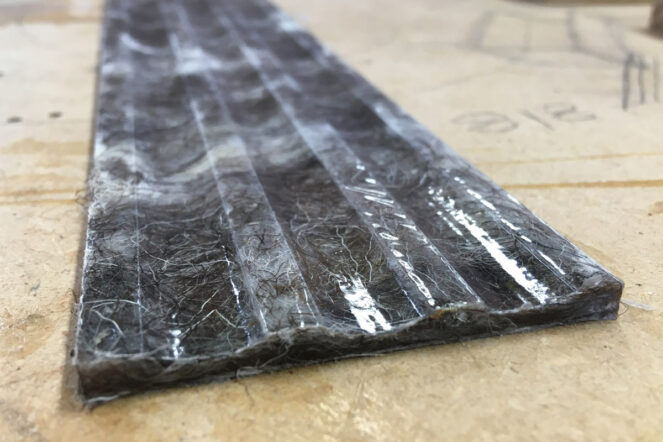

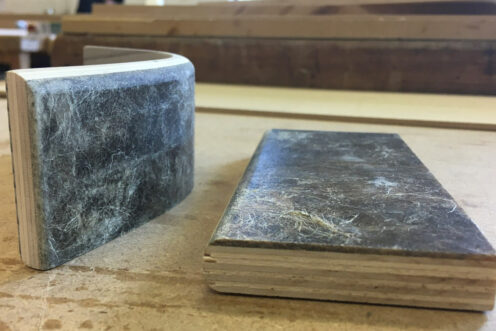

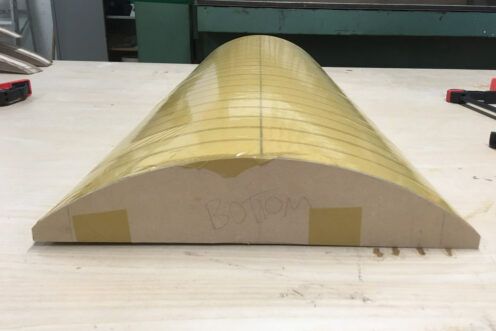

Following this, Andrew decided that the best way to pursue this would be to use it as a laminated surface; steam bent to form a constructional veneer. Rounded edges were easily achieved on the router table, aided by the smooth cut of the resin.

Due to the initial design changing, Andrew decided to create a shaped mould in order to form channels into the surface. These channels act as registration points for smartphones and tablets to be placed, while also adding stability.

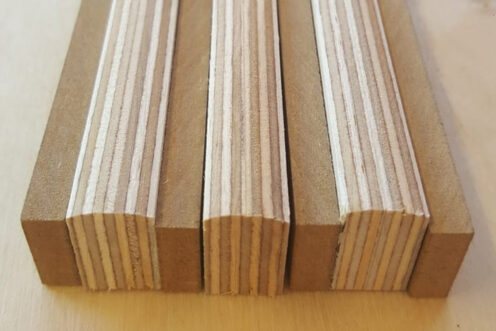

The next stage of the make was the laminating of the ash doors, which have a surface laminate of the wool composite. Once the core had been made, a carefully book-matched piece of the same constructional veneer was added for the interior. This was followed by a wool composite surface laminate for the outside. The process was completed immediately after the wool had been pressed, as the flexing was more effective when it’s not fully cured.

The finished result

Thank you to Andrew for sharing this project with us, we can't wait to see what else you create!

Want to know more about EcoPoxy? Take a look at our Knowledge Blog to discover more about the natural Epoxy & Resins for Woodworking or browse the EcoPoxy range...